Hand-In-Scan

Hand Hygiene Scanner

Designer: Ferenc Laufer, Andras Hunfalvi

Client:HandInScan Zrt.

Hand-in-Scan is a multiple-award-winning, Hungarian medical innovation with the mission to stop secondary infections in healthcare settings. It is commercially available and used in many facilities world.

Even in developed countries, thousands of people die every year from (nosocomial) infections, acquired during hospital treatments, caused by inadequate hand disinfection of healthcare workers.

Hand-in-Scan is commercially available and used in many facilities worldwide.

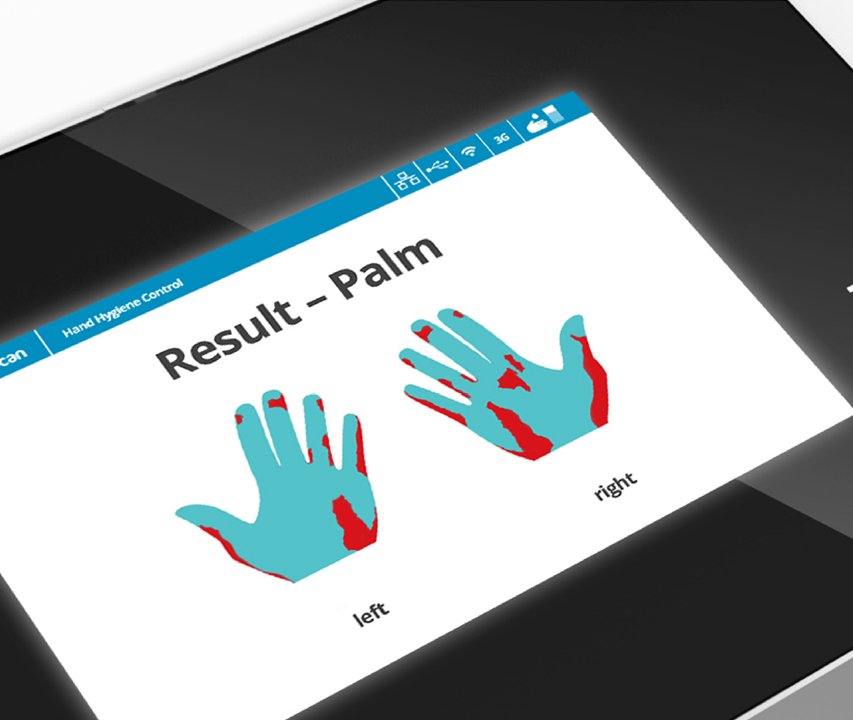

Operating principle

The device uses ultraviolet light, digital imaging and artificial intelligence software methods to distinguish sanitised versus infected areas after hand washing. The users perform hand washing with an UV-marked substance which appears brighter on surfaces sufficiently treated with the alcoholic disinfectant. Inside the body of the device, wide angle cameras take pictures of the hands in the UV-lighted box. The palmar and the dorsal sides of the hand are recorded or dual-side imaging is performed on one hand at a time. Results are processed by the device and then shown on the monitor. Later data can be accessed from the reporting platform and easily evaluated.

Product Design

As a medical device, Hand-in-Scan had to comply with strict hygiene and usability standards. It is easy to clean and keep clean, wall-mounted and robust enough to take thousands of scans each day. The casing is made of anodized aluminium and its features lead the hands of the users inside the body of the device without having to touch anything.

How do design and technical content influence each other?

Hand-in-Scan was able to win multiple design awards in addition to medical awards because of the effective and constant communication and cooperation between the developer team and the designers. Thanks to this careful process, the product could develop organically through many rounds of testing. Although it can be time-consuming progress, it guarantees success and return of investment, which can also be measured financially.

The best example of the cooperation was the placing of the motherboard, which was determined by the form of the casting. On the first prototypes the user should have touched the device, which turned out to be ineffective after various test rounds.

The final product no longer requires any activity from the user, they only need to place their hands in the device and the process runs independently.